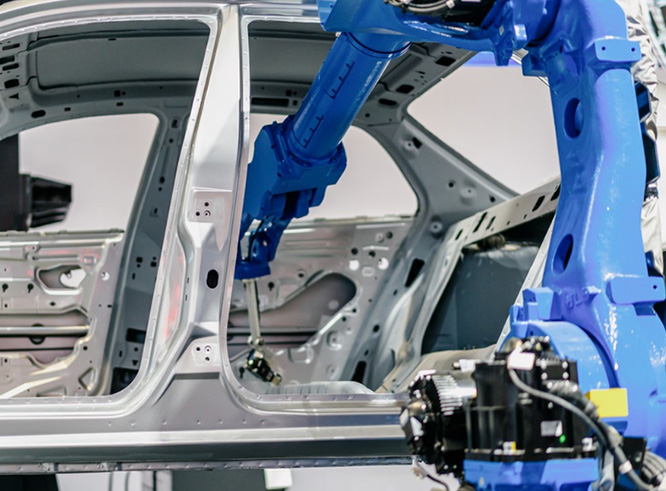

Сварочная машина робота

Сварочная машина робота

В основном кабеле используется специальный кабель с высокой гибкостью для робота

В основном корпусе используется специальный кабель для робота с высокой гибкостью.

Встроенный трехфазный трансформатор, изолированный от 380 В до 220 В для более стабильного электроснабжения. Оснащен трехфазным фильтром, эффективно улучшающим характеристики ЭМС и ЭМП

Встроенный трехфазный трансформатор с изоляцией 380 В и 220 В для более стабильного электроснабжения. Оснащен трехфазным фильтром, эффективно улучшающим характеристики ЭМС и ЭМИ.

Двухконтурная трахея в соответствии со сварочными требованиями

Обеспечьте двухконтурные воздушные трубы для удовлетворения потребностей в сварке.

Внутренний диаметр 6-осевого центрального отверстия составляет 44 мм, что может удовлетворить требования к установке пистолетов с водяным охлаждением и пистолетов с гофрированными трубами

Внутренний диаметр центрального отверстия 6-осевого двигателя составляет 44 мм, что может удовлетворить требования к установке пистолетов с водяным охлаждением и пистолетов с гофрированными трубами.

Встроенный высокоэластичный сварочный кабель

Встроенный высокоэластичный сварочный кабель.

| Модель лазера | Волоконный лазер |

| Мощность лазера | 1000 Вт, 1500 Вт, 2000 Вт, 3000 Вт |

| Длина волны лазера | 1070 ± 10 нм |

| Режим работы | Непрерывный/модулированный |

| Сварочный материал | Углеродистая сталь, нержавеющая сталь, оцинкованный лист, алюминий, медь и т. Д |

| система управления | Система управления лазером Ml |

| Режим прицеливания и позиционирования | Индикация красного света и прямая линия красного света (опционально ПЗС-наблюдение) |

| Режим охлаждения | Циркуляционное водяное охлаждение |

| Средняя мощность | 5,76 кВт 7,26 кВт 8,1 кВт 12,06 Вт |

| Потребляемая мощность | Переменный ток 220/380 В 50 Гц |

| Точность повторения робота | 0,05 мм |

| Выставка роботов-манипуляторов | 1450мм |

| Нагрузка манипулятора | 10 кг |

| Количество осей робота | 6 осевых |

Область применения: автомобилестроение, судостроение, аппаратные изделия, оборудование для фитнеса, аэрокосмическая промышленность, строительная техника

Дисплей образца